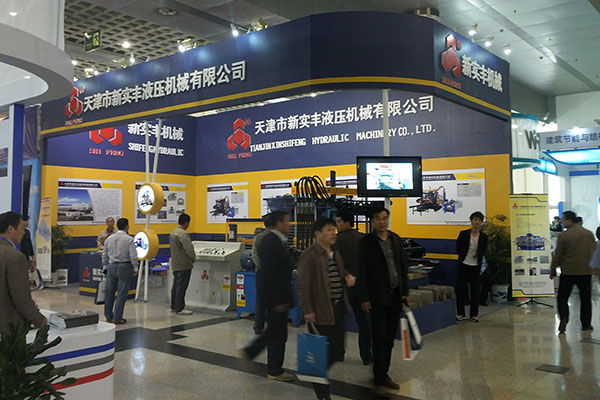

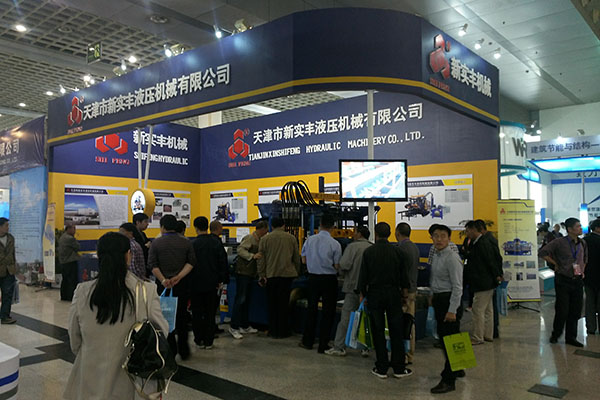

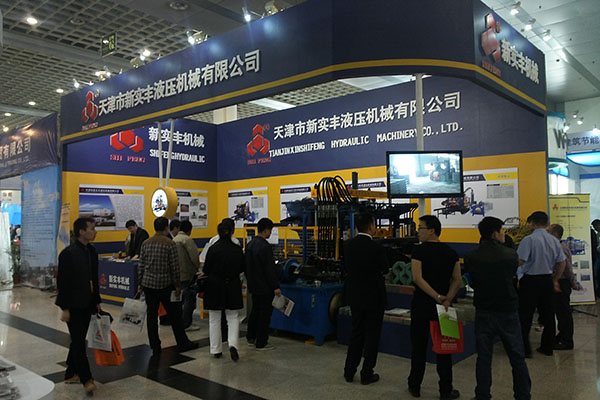

SHIFENG GROUP, in the spring of 2014,took part in Shan Dong province building machinery exhibition with full auto QT5-20A3 block machine,which was very popular for domestic and foreign construction markets.The concrete block making machine, displayed on the 40㎡stand,attracted a lot of local and other places customers,even foreign customers.

We introduced the brick making machine to our customers on the topic of making bricks that our customers were most concerned about.

Firstly,we listed different kinds of block and brick proportion and materials for customers reference.

|

Raw Materials Proportion of Block |

|||

|

Block Type |

Layer |

Materials |

Proportion(Weight) |

|

Hollow Block |

Nil |

Concrete |

10% |

|

Sand |

40% |

||

|

Stone Powder |

35% |

||

|

Slag |

15% |

||

|

Road Brick |

Face Layer |

Concrete |

30% |

|

Sand |

70% |

||

|

Pigment |

0.01% |

||

|

Glue |

Optional |

||

|

Aggregate Layer |

Concrete |

15% |

|

|

Sand(4-6mm) |

35% |

||

|

Sand(2-4mm) |

30% |

||

|

Stone Powder |

20% |

||

Secondly,the raw materials’ quality was important as well.Different quality of raw materials would make the proportion different.

Last but not least,the brick making machinery determined success or failure from production efficiency,brick quality to bock factory running cost.

In the construction machinery fair,we met many new customers and got high praises from old customers.SHIFENG GROUP is worth believing.

Post time: Apr-14-2020