Cemented tungsten carbide wire drawing die

Grades for tungsten carbide drawing dies

|

Grade |

Density (g/cm3) |

Hardness (HRA) |

TRS (MPa) |

Average Grain Size (um) |

|

YL01 |

15.25 |

93.5 |

3300 |

0.8 |

|

YL10.2 |

14.5 |

92.0 |

4000 |

0.8 |

|

YG6 |

14.95 |

90.0 |

2400 |

1.6 |

|

YG6X |

14.95 |

91.5 |

1900 |

1.0 |

|

YG8 |

14.75 |

89.5 |

2800 |

1.6 |

|

YG11 |

14.4 |

87.5 |

3100 |

1.6 |

|

YG15 |

14.05 |

87.0 |

3000 |

1.6 |

|

Grade |

Application Recommended |

|

YL01 |

Used sor drawing diameters less than 1.5mm of steel, tungsten and molybdenum wire under high speed |

|

YL10.2 |

Used sor drawing diameters between 1.5mm to 10mm of steel, tungsten and molybdenum wire under high speed drawing as well as nonferrous tubes with high requirements on surface finish. |

|

YG6 |

Used sor drawing diameters less than20mm of steel, nonferrous and its alloy wire or bar under a mede- -rate stress. It's also used for tubes less than diameters of10mm. |

|

YG6X |

Used sor drawing diameters less than20mm of steel, nonferrous and its alloy wire or bar under a mede- -rate stress. It's also used for tubes less than diameters of10mm. |

|

YG8 |

Used sor drawing diameters less than 50mm of steel, nonferrous and its alloy wire or bar under a mede- |

|

YG11 |

Used sor drawing diameters less than 60mm of steel, nonferrous and its alloy wire or bar under a mede- |

|

YG15 |

Used for steel pipe and steel bar as well as alloy steel bolt and head forging of rivet under a certain big stress. |

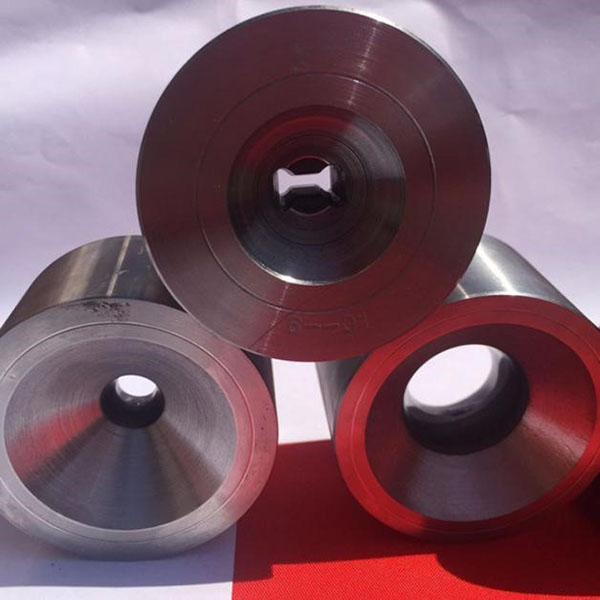

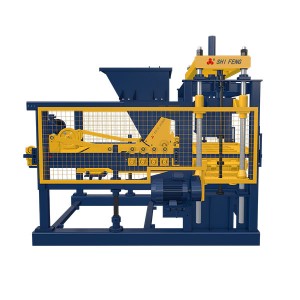

PRODUCTION DISPLAY