Auto Brick Machine - Concrete Block Making Machine QM5-18 – Shifeng

Auto Brick Machine - Concrete Block Making Machine QM5-18 – Shifeng Detail:

|

QM10-15 Parameters |

|||

|

Dimension of host machine |

6923*2100*2500mm |

Total power |

38Kw |

|

Cycle time |

18s |

Rated pressure |

14Mpa |

|

Height of finished products |

50-200mm |

Forming area |

1100*500mm |

|

The applicable type of brick pallet |

bamboo plywood, steel plate, plastic plate,plank,GMT,etc |

Voltage |

AC380V |

|

Warranty |

One Year |

After-sales Service Provided |

Available |

|

Brick Raw Material |

Concrete |

Patent Product |

Yes |

|

Vibration System |

Variable frequency automatic control |

Brick Pallet Size |

1150*580*(12-25)mm |

|

QM5-18 Productivity |

|||

|

Brick Size(L×W×H) |

Pcs/Mold |

Pcs/ Hr |

Pcs/ 8 Hrs |

|

390×190×190mm |

5 |

1000 |

8000 |

|

240×115×53mm |

34 |

6800 |

54400 |

|

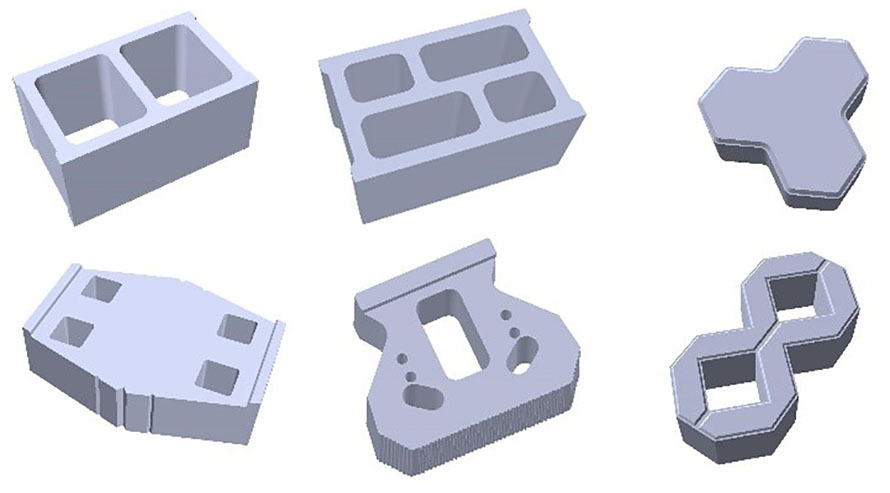

Specializing in hollow blocks |

|||

|

ALL KINDS OF BLOCKS CAN MAKE |

|||

|

|

|||

1. The rational design prolong using life-span

2. Machine has advantage of save energy ,save raw materials and environment protection

3. The machine has function of Self-diagnose

4. Stable and reliable performance,easy operation.

5. It’s passed ISO9001,CE,owned patents and honors for concrete block making machine.

6. Complete solution for plant set up and all kinds of wastes recycle technologies.

7. CHARACTER:

Remote service system R&D by SHIFENG, To monitor machine produce online and generate the running report, remote diagnose malfunction and update, automatic trouble-shooting &maintenance

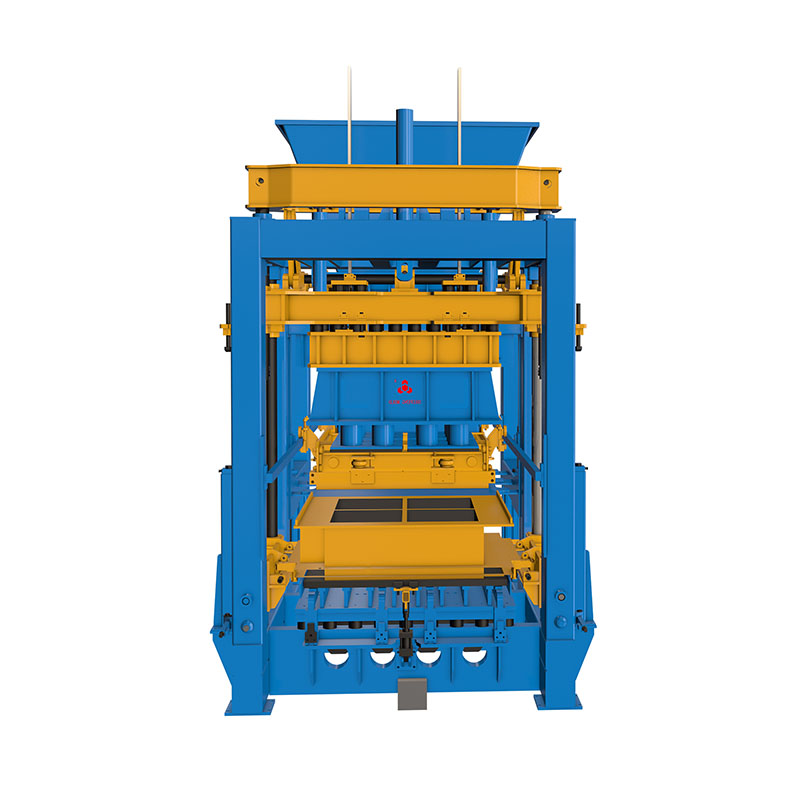

Block Machine Host

The host adapt High-strength gantry Frame, 4 guidepost (chrome plated) ,elevator can be adjustable according to the high of the mould,easy operate. Shift-fork waving feeding system with merit for speed fast and high density. Suspension type 4direction position batching machine (patent :ZL2012 2 0394056.6) to reduce running resistance,save consumption,can solve the tolerance come from the pallet thickness.

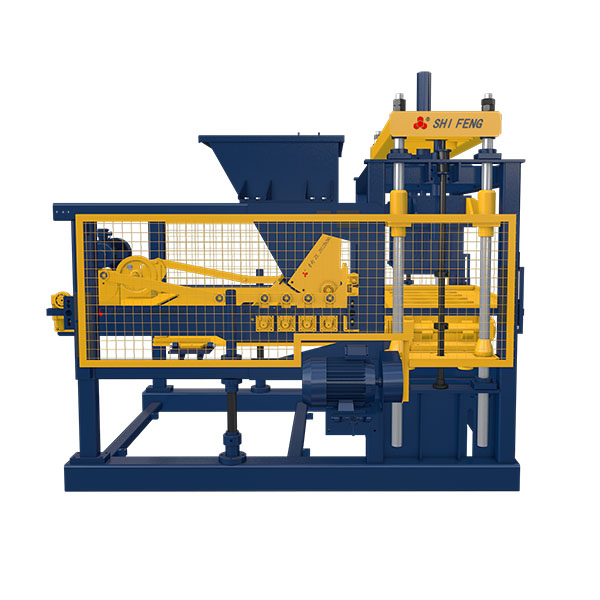

Hydraulic system

To adapt imported hydraulic components and double-ratio magnet valve to ensure machine chitinous ruining for a long time.

PLC, Electrical Parts ,Hydraulic Parts

ABB,OMRON, SIEMENS,SCHNEIDER

The host Machine

Fast speed for hollow blocks

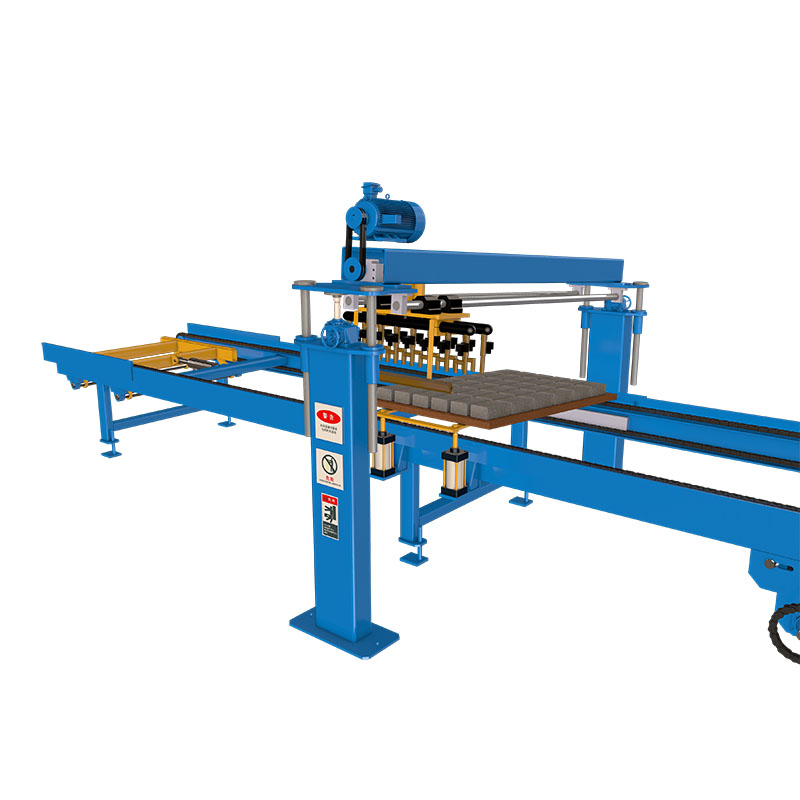

Product detail pictures:

Related Product Guide:

Our company puts emphasis on the management, the introduction of talented personnel, and the construction of staff building, trying hard to improve the quality and liability consciousness of staff members. Our company successfully attained IS9001 Certification and European CE Certification of Auto Brick Machine - Concrete Block Making Machine QM5-18 – Shifeng , The product will supply to all over the world, such as: Turkey , Belgium , St. Petersburg , During in 11 years, We've participated in more than 20 exhibitions, obtains the highest praise from each customer. Our company has been devoting that "customer first" and committed to helping customers expand their business, so that they become the Big Boss !

The product classification is very detailed that can be very accurate to meet our demand, a professional wholesaler.